Continuous Improvement

Seeking 1% improvements everyday

Lean construction emphasizes the importance of continuous improvement, which is the idea that every process and activity can be improved by learning from mistakes, feedback, and data. Donley’s is constantly seeking and obtaining feedback from those closest to the work to find 1% improvements every day.

Why 1% improvement

One of the books that inspired Donley’s to adopt Lean construction principles and continuous improvement is Atomic Habits by James Clear. In this book, Clear explains how small changes can lead to remarkable results over time. He calls this the compound effect of habits, which means that improving by 1% every day can result in a 37-fold improvement in a year. Conversely, declining by 1% every day can lead to almost zero in a year.

The benefit of 1% improvements is that they are easier to achieve and sustain than big leaps. They also create a positive feedback loop that reinforces the desired behavior and builds momentum. By focusing on the process rather than the outcome, 1% improvements help to overcome the challenges of motivation, procrastination, and inconsistency. They also allow for adaptation and innovation, as the feedback from each improvement can inform the next one.

How Donley’s applies continuous improvement

Donley’s applies the principle of continuous improvement in every aspect of its business, from project planning and execution to personnel development. Some of the ways that Donley’s implements continuous improvement are:

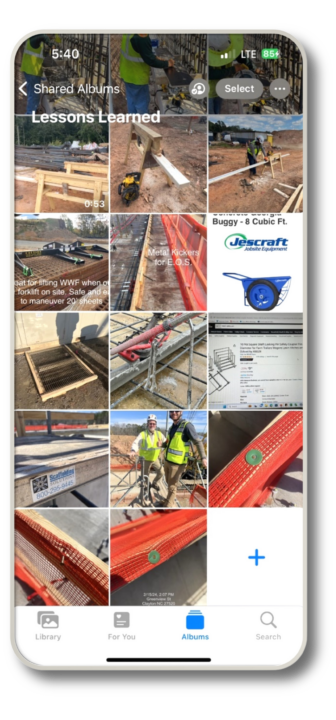

Lessons Learned Album: Best practices and lessons learned are captured with pictures via phone in real-time, then posted to a shared album so all employees have access to the latest and greatest information.

First Run Studies: Donley’s FRS process has evolved over time to include 54 specific FRSs, 8- and 2-week activities, on multiple pages with photos from lessons learned. Examples of these include cast-in-place walls, columns, decks, and stairs. These workbooks are designed to help those who are new or inexperienced in planning the work by showing them what works and what doesn’t. They include lessons learned from past projects that can be applied to all projects moving forward.

5S: The five Ss stand for sort, set in order, shine, standardize, and sustain. Donley’s continuously improves its standards through an employee feedback cycle, and sustaining the best practices moving forward.

Project Management and Superintendent Trainings: Donley’s holds on-premise trainings multiple times per year. We bring in staff from all offices for two days to teach standards, best practices, and other Lean principles. As a result, we gain valuable feedback on areas we can improve.

What are the benefits of continuous improvement?

By applying the principles of continuous improvement, Donley’s has been able to achieve significant benefits for its projects and its organization. Some of the benefits include:

- Boosted labor productivity and efficiency

- Elevated product quality and reliability

- Strengthened customer satisfaction and trust

- Reduced costs and mitigated risks

- Increased innovation and competitiveness

- Improved employee engagement and retention

- Accelerated employee development