Safety

Safety is our culture. Our daily goal is to operate incident free.

To operate incident free, we believe safety is practiced 24/7, whether we are on the job or off. Safety plays the most significant role in our overall operations and, is supported by our Safe-D program to reinforce safety as the premier priority at work and at home.

Safety is fully integrated into all of our operations. Our "I will not look the other way" philosophy puts the responsibility for safety on all employees, as well as anyone entering the jobsite. Our “One Team” approach allows for our operations and safety personnel to work in tandem towards the goal of keeping all jobsites incident-free every day.

Why is safety at the very core of Donley’s culture? The answer is simple. We want our employees, workers, subcontractors, and the public that surrounds them to go home safe to their families each day.

Training and certification

All workers must complete Job-Specific Safety Orientation before working on any Donley’s job site. After completing the orientation, a job-specific hard hat sticker is issued and is a mandatory requirement before starting work on a job site. Other focus areas of safety training include:

- CPR Training

- Signaling and Rigging

- Fall Protection

- Hazard Communication

- Silica Awareness

In addition, all of our senior management, project managers, superintendents, and foremen are given 30-hour OSHA training.

No Atajos = No Shortcuts

Employees are six times more likely to be injured from unsafe behaviors (such as taking shortcuts) than from being exposed to unsafe working conditions according to Safety Matters Weekly.

Our OSHA recordable rate is significantly lower than the national average for concrete contractors

Measuring safety

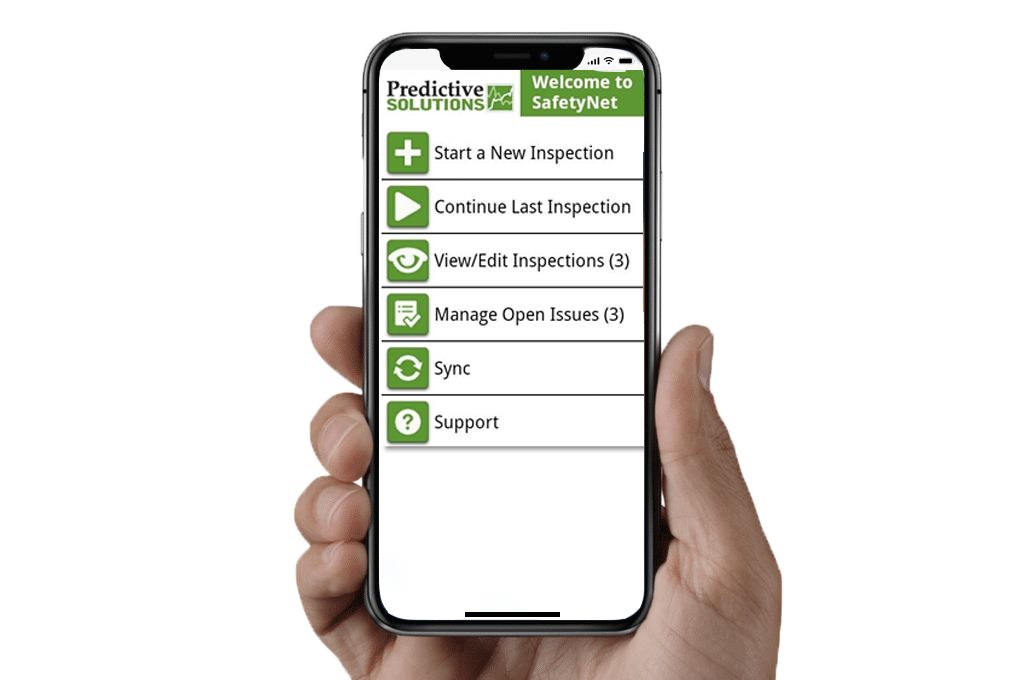

Donley’s utilizes Predictive Solutions SafetyNet to track and trend safety audits on all of its projects. This invaluable tool is used for: tracking the trends of at-risk behaviors, tracking safe observations, safety accountability of project teams, incident tracking, and evaluating subcontractor safety performance (part of our subcontractor prequalification process).

We use this data to generate KPI’s that our management team reviews every week. This in turn helps us put in place irreversible fixes to keep safety issues from repeating in the future.

QUESTIONS?

Our team is here to help get you answers.